Description

As with previous Emerald ECUs the K6+ continues to provide class leading features with intuitive and easy to use software combined with future proof upgrade options. The K6+ currently uses the already established K3 PC software providing intelligent and proven functionality and features, such as Adaptive Lambda control, Closed loop Boost and EGT control, VVT control and Triple MAP switching.

Specification:

Physical

- Dimensions: 110 x 190 x 44 mm (W x L x H)

- Weight: 491g

- Power supply: 6.5v – 18v

- Environmental protection: IP65 sealed enclosure, IP68 water proof connectors

Inputs

- Engine speed triggers: 3 inputs, each configurable for Inductive or Digital sensors, crank, cam or distributor. User selectable crank trigger patterns.

- Air Temperature: Yes, standard Bosch or user programmable characteristic

- Coolant Temperature: Yes, standard Bosch or user programmable characteristic

- Barometric Pressure: Internal barometric pressure sensor

- Engine load: Throttle pot and/or MAP 0 – 5v signals

- Lambda sensor: 0 – 1v (Narrow band) or 0 – 5 v (Wide Band) signals

- Road speed: Up to 4 inputs, configurable for inductive or digital sensors, software switchable internal pull-up option.

- Other: Coded immobiliser input, exhaust gas temperature, oil/aux temperature. Spare inputs can be assigned to air conditioning request, boost level adjustment, clutch switch, triple map selection, launch enable, and others…

Outputs

- Ignition coil drivers: 6 internal drivers, configurable as Active high for external amplifier control or Active low for direct coil control

- Injector drivers: 6 internal high power drivers

- Other: Air conditioning clutch, fuel pump relay control, supply relay control, two stage cooling fan control, programmable tacho driver, oxygen sensor heater control, shift-light, boost control valve, variable cam control, cam switching, single & twin PWM solenoid IACV control, Bipolar & unipolar IACV stepper motor control, user programmable outputs, 5v sensor supply

Data-link Interfaces

- RS232 serial communications port

- Controller Area Network (CAN) interface. Version 2.0B protocol at up to 1Mbit/sec

K6+ Additional Features:

K6+ Additional Features

- Any number of cylinders from 1 to 12

- Sequential ignition and injection to six cylinders

- Triple live map switching (engine running)

- USB with Wi-Fi link to phone or tablet device

- Twin Lambda input (for V Engines)

- Load from TPS or MAP sensor (or combination)

- Double injector control

- Closed loop fuelling

- Adaptive mapping from a wide band lambda sensor

- Boost control

- Boost adjustment with different gears

- Boost dash override.

- Boost Vs EGT function

- Over-boost protection

- Hard cut rev limit

- Soft cut rev limit

- Coolant fan control x 2

- Air Conditioning control

- Idle stabilisation using ignition advance

- IACV control for 2/3/4/5 wire motors

- Adjustable speed sites

- Adjustable load sites

- VVT cam control

- VVC cam control

- VTEC switching

- Internal Barometer correction

- Drive-by-wire (DBW)

- Programmable pedal mapping

- Throttle blip function (sequential gearbox)

- Flat shift (H-Pattern or sequential gearbox)

- Traction control

- Launch control

- Distributor or trigger wheel driven (14 different trigger patterns available)

- CAN BUS

- Direct link to AIM and Race Technology Dash

- Battery voltage compensation

- Mapped coil-on time

- Internal or external ignition amp control (coil-on-plug possible)

- Road speed limiter (requires wheel speed input)

- Keep-alive after key off (Turbo spin down)

- Overrun fuel cut-off

- Oil pressure protection input

- Fuel pressure input

- Flex fuel sensor input (E85/Petrol % volume)

- 20,000 rpm capability

- Digital or inductive sensor inputs

- Tacho driver/tell-tale

Additional Features:

Adaptive Lambda control: Self learning fuelling capability

The 16 x 32 cell AFR target table allows you to set the desired AFR that you wish the ECU to target for any given speed or load site. In addition, the 16 x 32 cell AFR corrections table allows you to view/ edit/ apply the fuelling corrections built up in the ECU while in adaptive mode. The 16 x 32 cell Feedback mode table allows you to set the mode of operation (open loop, closed loop, adaptive) for any given speed or load site.

By utilising any of the aftermarket wide band lambda sensors with a capability to output a 0-5v signal the K6’s adaptive mapping capability can be used. Fully user configurable with 3 modes of operation – open loop, closed loop and adaptive you can now have exactly the air to fuel ratio that YOU want anywhere in the speed and load range.

Adjustable speed and load sites: Tailor maps for your engines specific requirements

32 speed sites (rpm) Speed sites are adjustable to a resolution of 1 rpm.

To deal with specific rpm and/or load related issues that arise on different engines (abrupt airflow changes due to cam timing, TB design or boost onset) the K6 speed and load sites are fully user configurable. Changes made are propagated through all maps and can be made at any time.

CAN bus: Link to other CAN enabled devices

The K6 output’s a steady stream of up to 21 data parameters; 20 times a second which can be used by other CAN enabled devices – i.e. Digital dashboards. Emerald’s CAN protocol is freely available and can be downloaded from our Software & Manuals page.

Closed Loop EGT control: Adjust boost pressure and fuelling to control port temps

The ECU can be configured to read exhaust gas temperature via a signal conditioning unit. To ensure the best accuracy, the exhaust gas temperature is transmitted digitally between the signal conditioning unit and the ECU. Either an Emerald or VAG signal conditioning unit can be used.

Exhaust gas temperature is a critical measurement for all engines. The K6 ECU can utilise exhaust gas temperature from a suitable thermocouple and conditioning unit. User configurable maps allow reductions to boost pressure and/or additional fuel to be introduced to safeguard the engine.

Enhanced Boost control: Tailor boost curves for your needs - variable by gear ratio

Electronic Boost control variable by engine speed, load and gear ratio. Enables precise control of boost pressures which can minimise turbo lag, propagate boost earlier and introduce boost progressively to maximise traction. In combination with map switching this becomes a very flexible and powerful feature.

Honda VTEC & VVT control: Control & utilisation of these clever mechanisms

Full, configurable control of the Honda VTEC system and also Variable Valve Timing Cam Phasers including the Rover variable cam duration (VVC) engine.

Cam on/ off switching control. Switch according to rpm and load. Any spare output can be assigned to this function. Rover VVC control. Continuously variable cam duration. Control target duration according to load and speed table. Oil temperature correction to control algorithm.

Map switching: Triple map facility

The ECU can store up to three completely separate maps. If set to do so the ECU will allow you to freely switch between maps on-the-fly. A 0-5 volt signal via an analogue input can be used to instruct the ECU which map to use. A simple two position on-off switch can be used to provide a high-low signal that will enable you to switch between two maps. To switch between three maps a rotary multi-position or potentiometer can be used.

User configurable and for most users operable from an in-car switch, this feature gives the user 3 completely different maps (including all map parameters) to configure as they see fit. We have seen this feature being used more and more over time with more and more ingenious uses.

Downloadable Documentation:

All Engine management systems are configured to order so the lead time can vary. Estimated dispatch time within 5 working days.

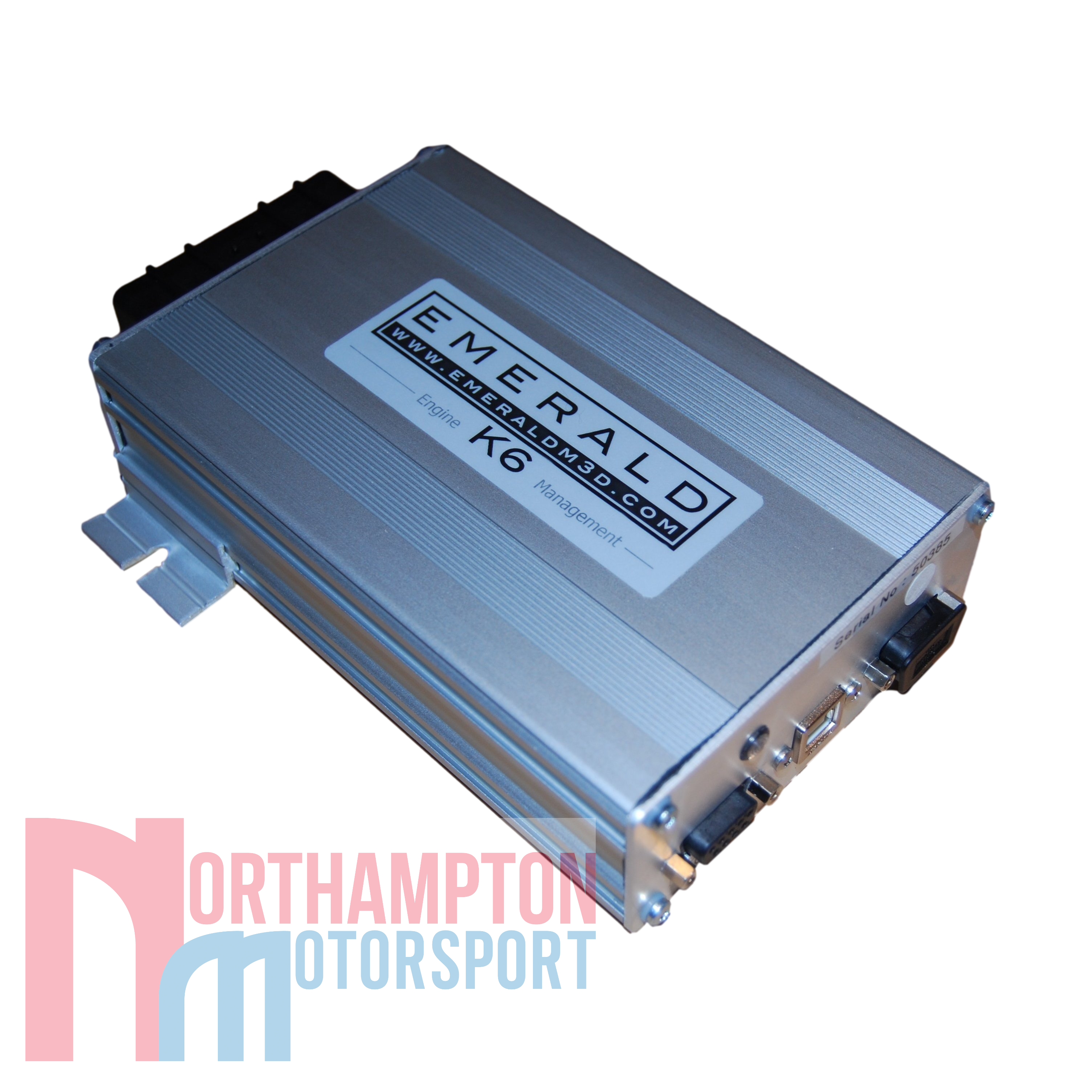

Picture for illustration purposes only. Actual parts may differ slightly in appearance.